Ul 300 Wet Chemical System

Ul 300 wet chemical system. June 10 2019 USD 40200-99800. UL-300 Wet Chemical Kitchen Hood System. All WHDR-250 500 Aqua-Blue Systems were not tested to UL-300 and are also not compliant.

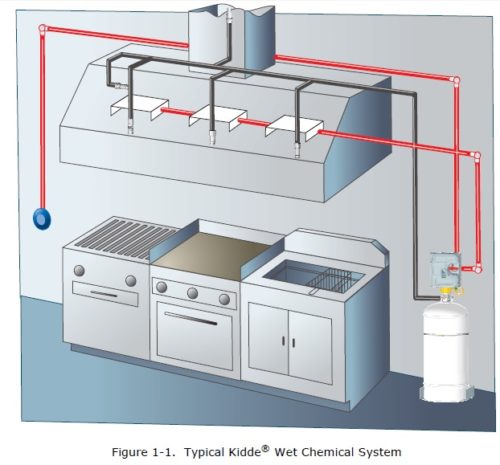

Do not attempt to retain any existing control heads nozzles discharge piping detection or conduit per NFPA 96. CMC 51322. Wet system nozzles are narrow typically ¾ inch to 1 inch in diameter and are typically covered with red orange or yellow plastic caps to keep them clean.

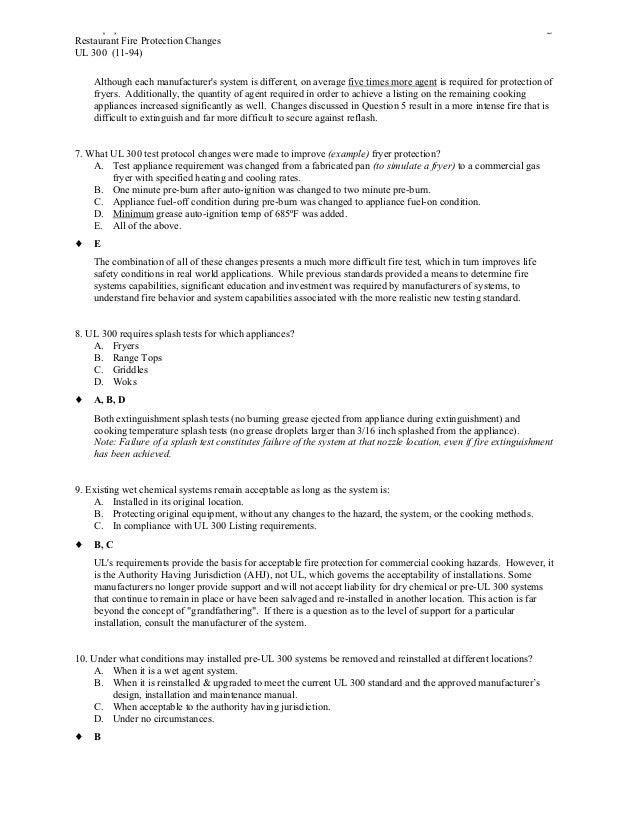

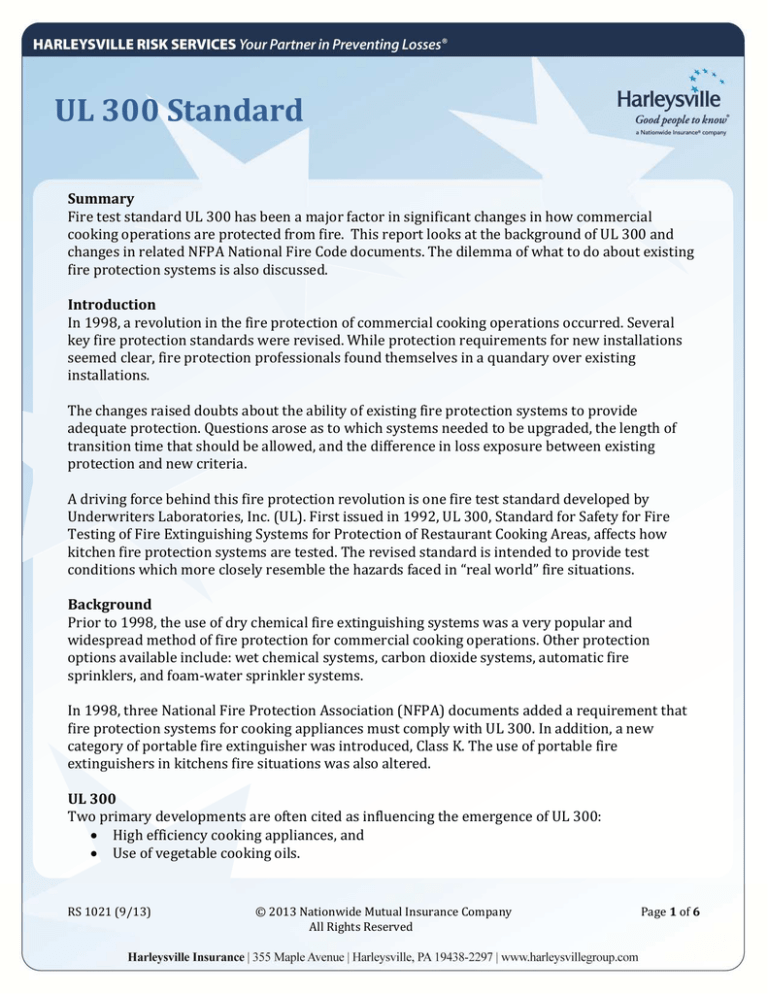

D Automobile Service Station Fueling Area Protection System A system arranged to discharge dry chemical directly onto small spill fires. Standard 300 Edition 4 Edition Date. This equipment shall only be protected with a wet chemical system as a dry chemical system has not been capable of meeting UL 300 standards due to re-ignition.

Fire suppression systems for protection of kitchen grease hoods meets new UL-300 codes paint booth and other industrial applications. Additional equipment is available for. Requirements for a UL-300 System.

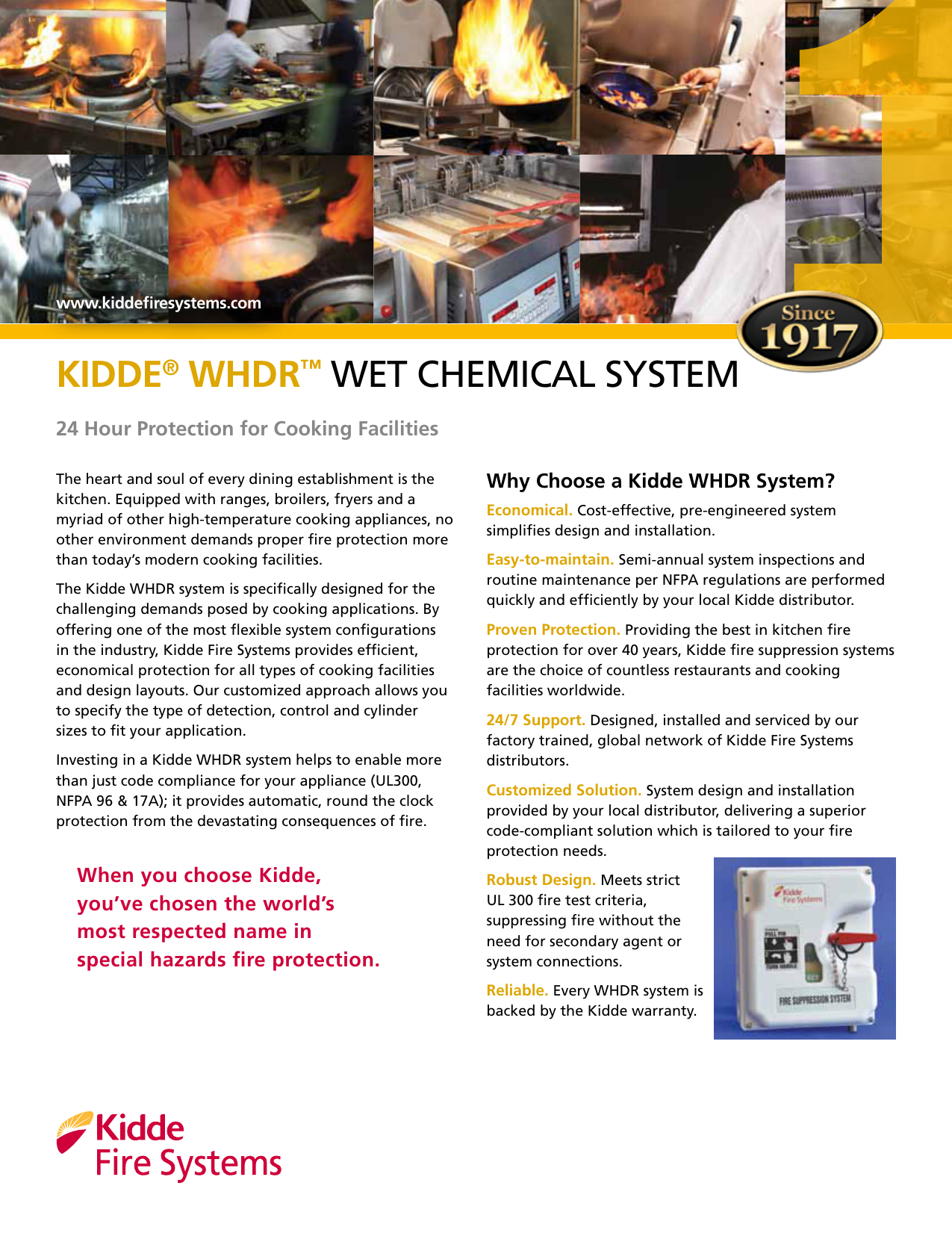

By offering one of the most flexible system configurations in the industry Kidde provides efficient economical protection for all types of cooking facilities and design layouts. The transition from dry chemical to wet chemical kitchen systems occurred due to changes in cooking oilgrease. It exceeds stringent UL 300 standard and complies with NFPA Standards 96 and 17A.

Automatic fire sprinkler systems. June 10 2019 ANSI Approved. Their Dry Chemical System was not tested to UL-300 Standard so it is not compliant.

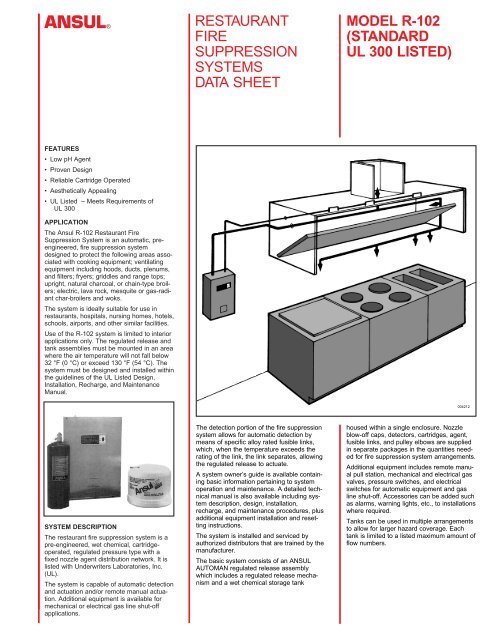

The system is capable of automatic detection and actuation andor remote manual actua-tion. The Fourth Edition of ULULC 300 has been issued to reflect the latest ANSI and SCC approval dates and to incorporate the proposal dated November 2 2018.

When the system is activated the wet chemical sprays onto the fire below and creates a chemical reaction called saponification.

Do not conduct a 6-month maintenance. Fire suppression systems for protection of kitchen grease hoods meets new UL-300 codes paint booth and other industrial applications. Nozzles located in the hood and duct Nozzles located over each cooking appliance Manual pull station Automatic fuel shut-offs for gas and electric UL-300 compliant wet chemical extinguishing system Wet chemical extinguishing system serviced semi-annually by an. June 10 2019 ANSI Approved. When the system is activated the wet chemical sprays onto the fire below and creates a chemical reaction called saponification. All existing dry-chemical and wet-chemical extinguishing systems shall comply with UL 300 no later than the second required servicing of the system following the effective date of this section. The Fourth Edition of ULULC 300 has been issued to reflect the latest ANSI and SCC approval dates and to incorporate the proposal dated November 2 2018. The WHDR system is specifically designed for the challenging demands posed by cooking applications. The dry chemical system failed to function properly and the insurance company denied coverage.

The dry chemical system failed to function properly and the insurance company denied coverage. Fire suppression systems for protection of kitchen grease hoods meets new UL-300 codes paint booth and other industrial applications. June 10 2019 ANSI Approved. A UL 300 compliant system uses a wet chemical extinguishing agent that takes longer to dissipate and allows the equipment and oils to cool adequately preventing re-ignition. The WHDR system is specifically designed for the challenging demands posed by cooking applications. A wet-chemical fire-extinguishing system that meets UL 300 criteria one of which is undergoing semiannual checkups by a certified professional In addition UL. Carbon dioxide extinguishing systems.

Post a Comment for "Ul 300 Wet Chemical System"